Symmetry Laminated Composites

Polymer composites in the aerospace industry 2015.

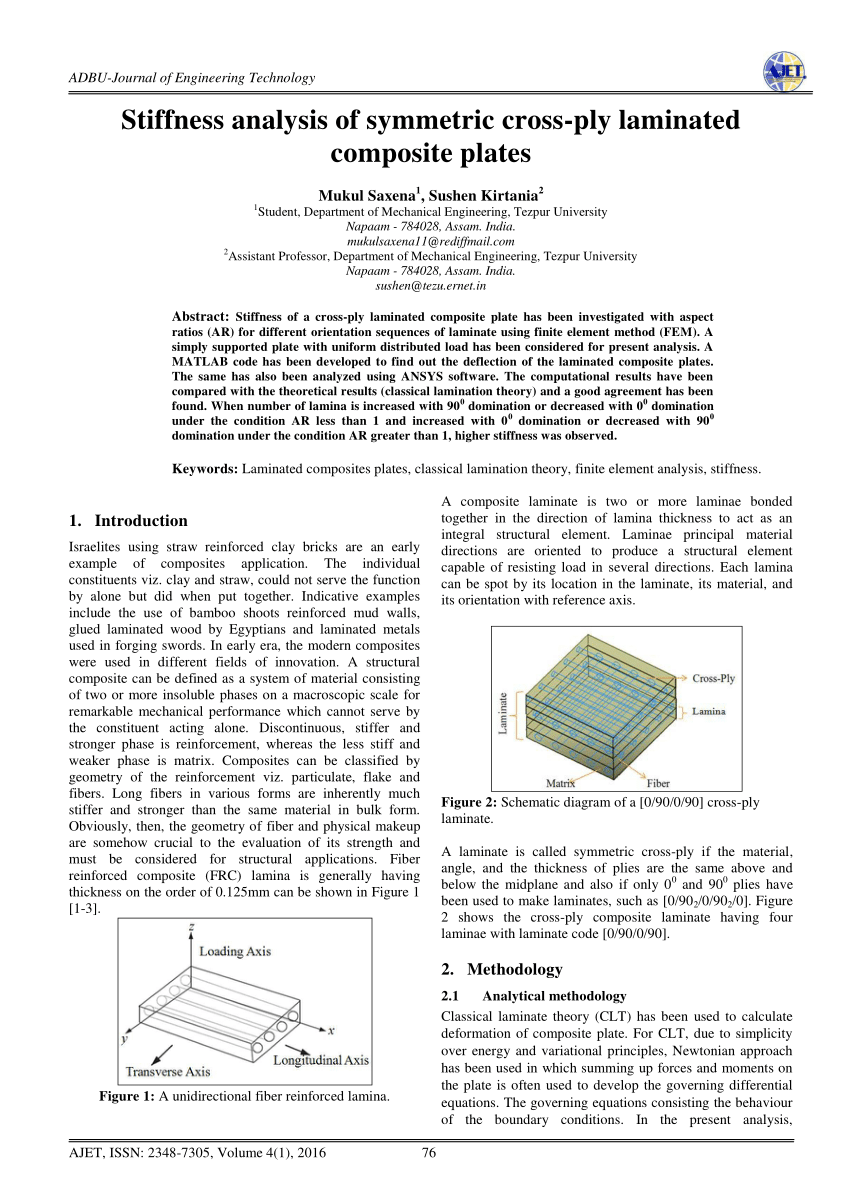

Symmetry laminated composites. Mid plane symmetry is generally preferred in practical design and manufacturing of laminated composites since it simplifies the design and manufacturing process and eliminates warping induced during cure e g causes the b matrix defined in appendix a to vanish. This not only simplifies the mechanical analysis but also gives desired mechanical performance. That the overall stiffness of fiber reinforced composite laminated plates is largely dependent on the fiber orientation. A symmetric fabric or laminate has ply orientations that are symmetric about the mid plane neutral axis.

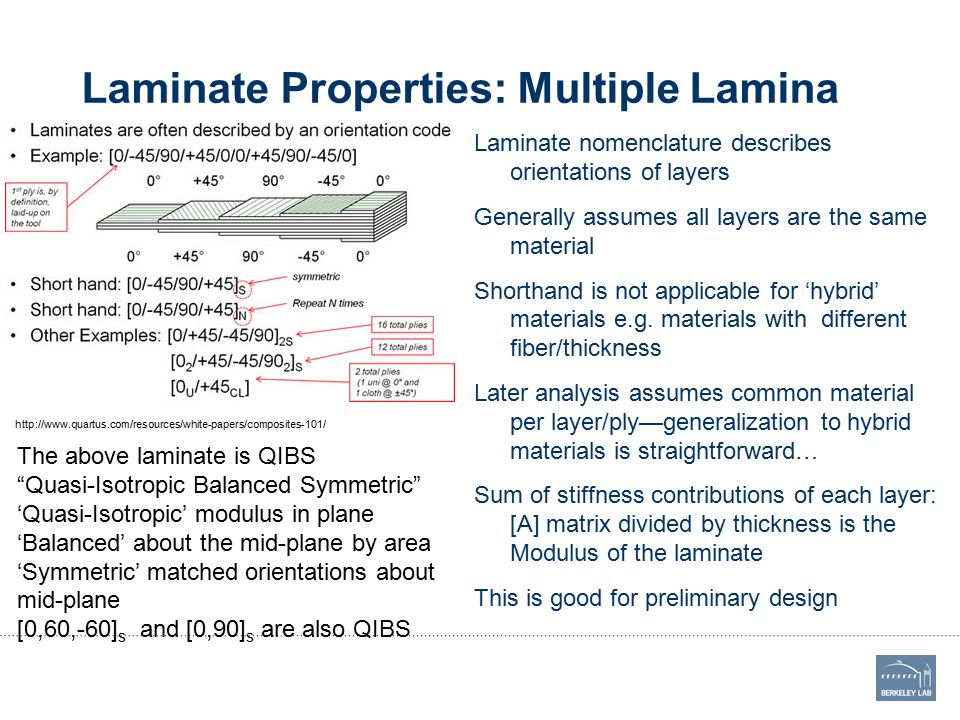

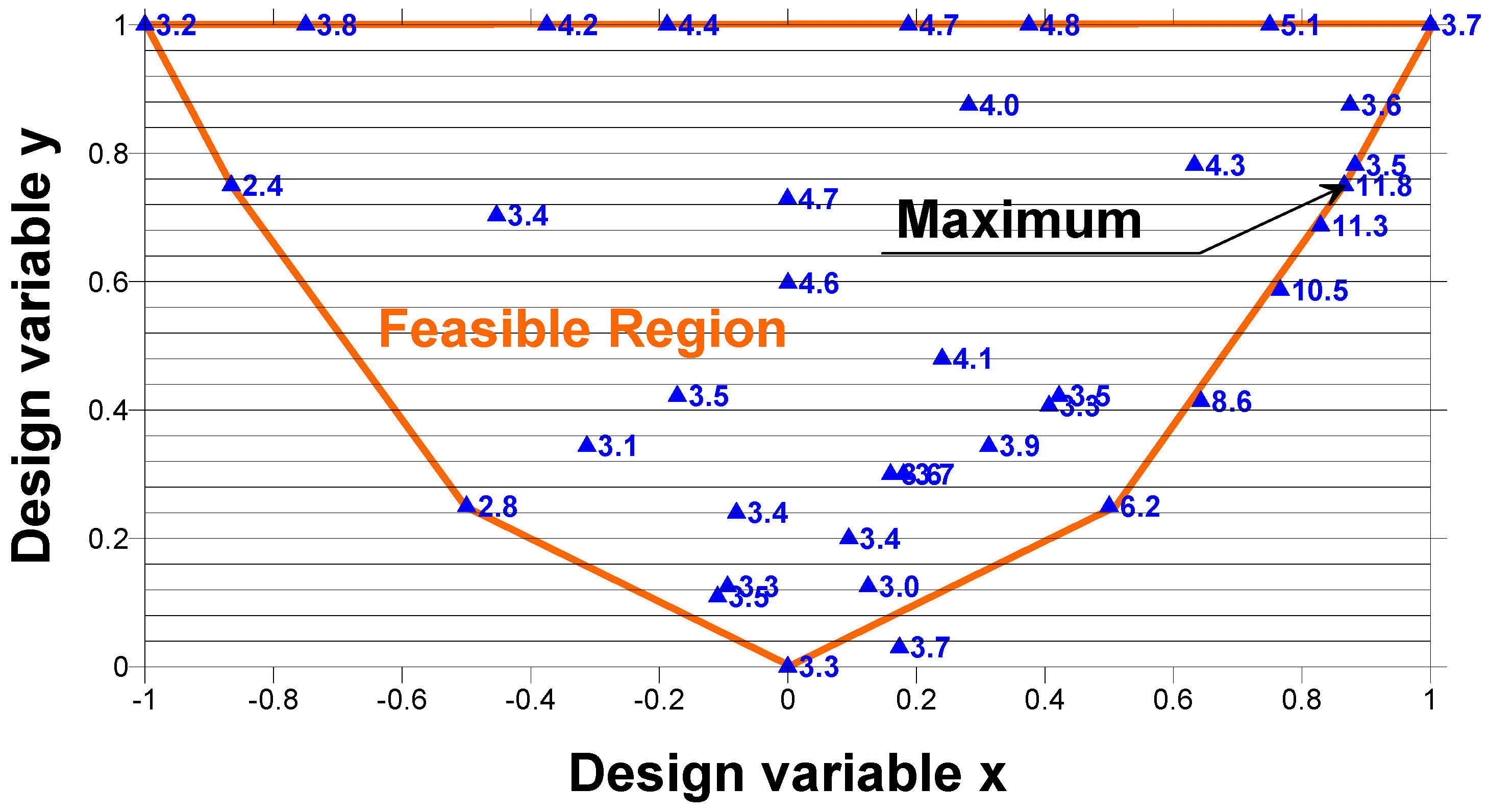

0 2548e 10 0 3554e 12 0 1639e 16 0 7218d 10 0 7125d 19 0 6022d 16. The purpose of the laminate orientation code is to provide a simple easily understood method of describing the lay up of a laminate. The symmetry or antisymmetry of a laminate based on angle material and thickness of plies may zero out some elements of the three stiffness matrices a b and d. Symmetry conditions or specifically the presence of stiffnesses b 11 and b 22 in woven fabric composites are also shared by anti symmetric crossply laminates 0 90 for example consisting of unidirectional composite laminae.

Geometric symmetry results from having identical lamina orientations above and below the mid surface. Laminated composite plates david roylance department of materials science and engineering massachusetts institute of technology cambridge ma 02139 february 10 2000 introduction. Laminate symmetry is necessary to maintain dimensional stability through processing. Balanced laminate balanced laminates are laminates in which for every θ ply θ 0 or 90 there is another θ ply somewhere in the stacking sequence.

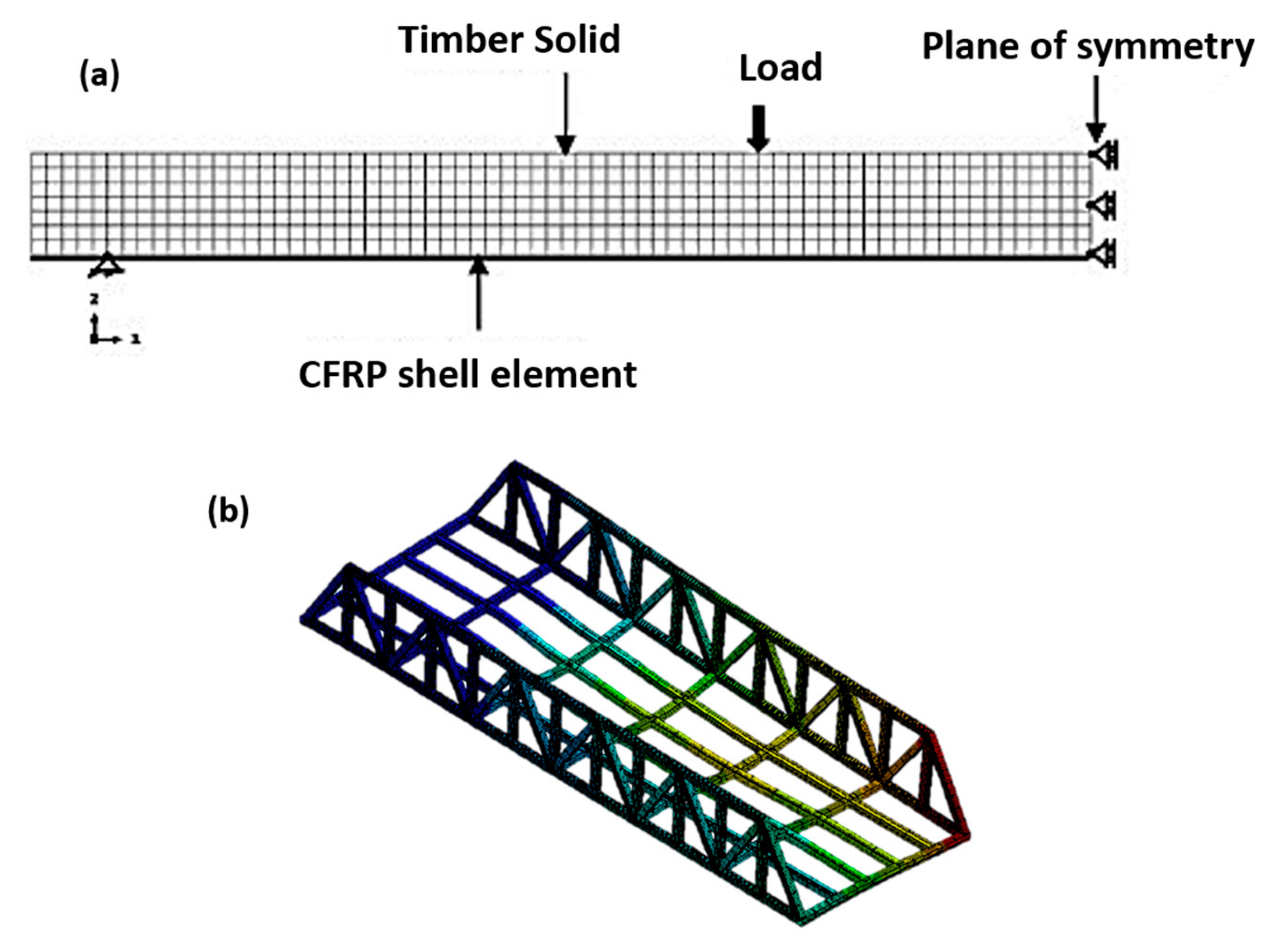

Meanwhile the study of elastic characteristics to non symmetric laminated composites due to the complexity has been limited on simple cylindrical and rectangular composite models. Laminated plates and shells are made by laying up and co curing unidirectionally reinforced fibrous composite plies or laminae which have different in plane orientation and are ordered in a certain stacking sequence. However most woven fabric composite laminates fail to behave completely like crossply laminates. The laminate orientation code is based largely on the code used in the advanced composites design guide shorthand to condense a long descriptive representation of a multi layer laminate into as.

Ply thicknesses are material system specific and their final magnitudes may depend on the fabrication procedure.