Sequential Lamination Designs

Phototool design sequential lamination when a sequential lamination process is utilized there.

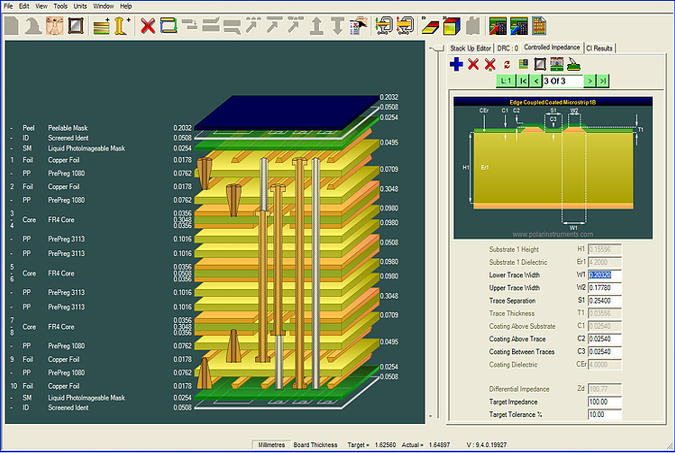

Sequential lamination designs. Power design services uses advanced sequential lamination technology allowing the manufacture of printed circuit boards pcb as the composition of different subsets of boards and layers. Again there are no stacked vias. Sequential lamination technology for high performance multi layer pcbs. This process is usually associated with via in pad technology when routing fine pitch densely routed designs.

Simply put this term describes the process of building up a pcb layer by layer using multiple subcomposites of copper and insulating pcb laminate material this technique allows for the completion of complex tasks such as trace routing on. The layer pair with the blind vias is prepared as if it were a two sided pcb. The pcb design to meet electrical timing and circuit signal quality. This build approach is the.

This is due to the nature of the very small drill and the aspect ratio requirement on all drills example 10 1 down to the inner layer. Many newer designs need sequential layers bonded one by one to provide for stacked or staggered microvias. The backbone of pcb fabrication the most fundamental manufacturing technique in modern pcb fabrication is sequential lamination. Sequential lamination will result in scaling factors that are different for each side of the material.

In a 2 n 2 stack up the 2 represents two sequential laminations. Including embedded resistor in printed circuit designs allows the resistors to be. A sequentially laminated printed circuit board pcb goes through at least two lamination cycles and can go through many more. For many materials multiple sequential lamination operations cause over cure and degradation of the laminate s resin.

The recommended phototool design guidelines for both sequential and standard lamination processes are described in the following sections. Sequential lamination is a variety of technologies where already laminated subparts or subcomposites are laminated to additional layer of copper or another subpart. A pcb subset is a multilayer printed circuit board presented in an almost completed pcb process. Sequential lamination of pcb layers is required in order to connect outer surface vias.

Steve robinson president and ceo ofapct stated material choice is a critical factor in the success with sequential lamination designs. As stated above 1 sequential lamination adds two copper layers so 2 sequential laminations adds 4 copper layers for a total of 6 layers. This is not a problem with arlon s 85n or 85hp products. Or create an unsolvable congestion in the design.

Sequential lamination where multilayer boards are formed by laminating together plated double sided or multilayers. Both products are used with as many as six sequential.