Sequential Lamination Definition

This process is usually associated with via in pad technology when routing fine pitch densely routed designs.

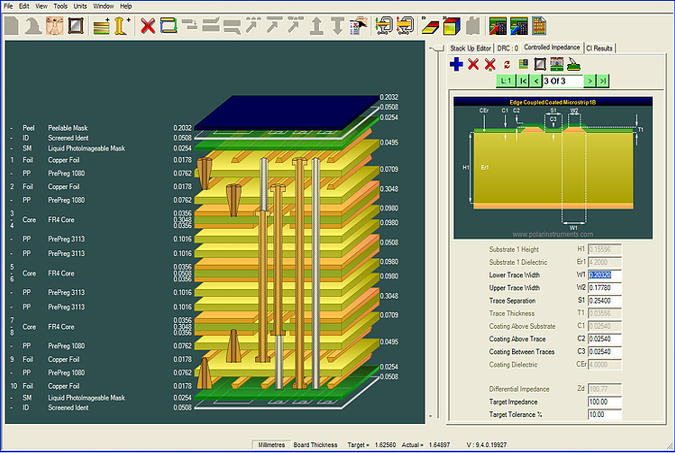

Sequential lamination definition. 3 plated closed with electroplated copper. Following a particular order. 4 screen printed closed with a copper paste. The process of manufacturing multilayer printed circuit boards in which multiple double sided layer stacks with interconnecting holes between conductive patterns on both sides are laminated or combined after which additional layers are attached to the partially completed board stack up.

Microvias can be filled with different materials and processes. Following a particular order. 1 filled with epoxy resin b stage during a sequential lamination process step. How to use sequential in a sentence.

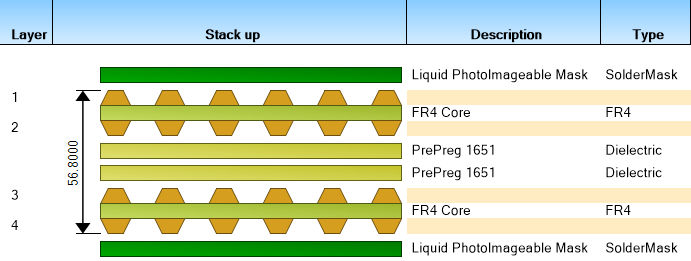

2 filled with non conductive or conductive material other than copper as a separate processing step. Sequential lamination of pcb layers is required in order to connect outer surface vias. Sequential definition characterized by regular sequence of parts. Sequential lamination is a variety of technologies where already laminated subparts or subcomposites are laminated to additional layer of copper or another subpart.

Following a particular order. Hdi pcbs are made through microvias buried vias and sequential lamination with insulation materials and conductor wiring for higher density of routing. Following a particular order. Power design services uses advanced sequential lamination technology allowing the manufacture of printed circuit boards pcb as the composition of different subsets of boards and layers.

Sequential definition is of relating to or arranged in a sequence. This build approach is the. A sequentially laminated printed circuit board pcb goes through at least two lamination cycles and can go through many more. Applications hdi pcb is used to reduce size and weight as well as to enhance electrical performance of the device.