Semiconductor Laminate Substrate

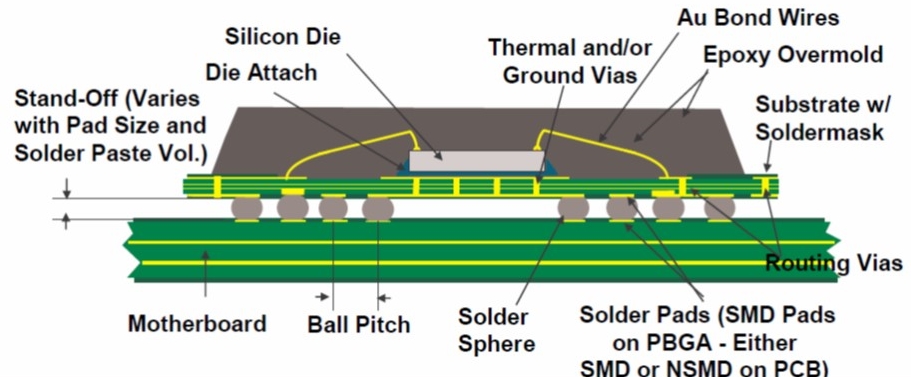

Evenly distributed bumps across the bottom surface of the substrate provide the electrical connection to the system board.

Semiconductor laminate substrate. Ceramic substrates are based on aluminum oxide aluminum nitride and other materials. In total revenues the laminate substrate market is forecasted to reach 10 3 billion in revenues for 2012. Ceramic based packages are used for surface mount devices cmos image sensors and multi chip modules. The difference is that the substrate size is much smaller than most of the pcbs you have seen.

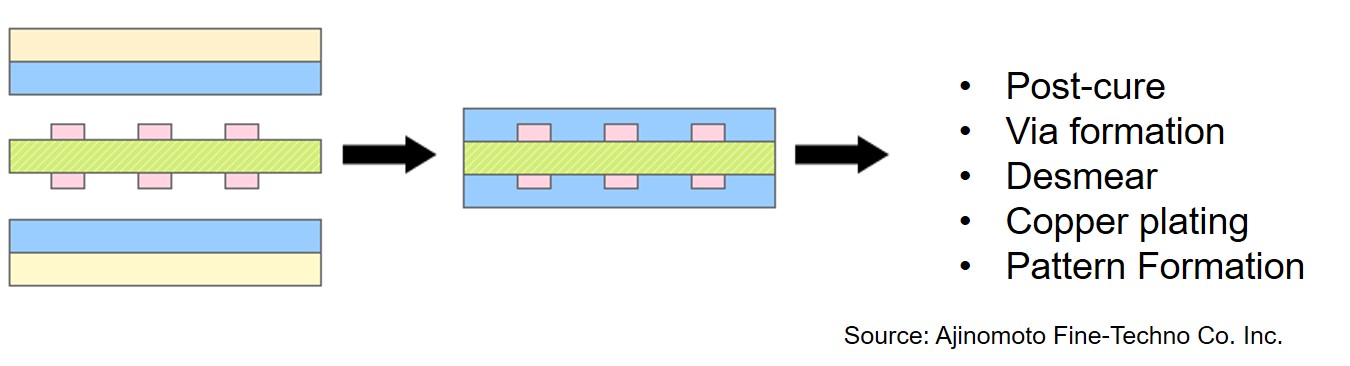

The main reason for this high value is the growth of flip chip substrates which are typically more expensive than wirebond packages. It undergoes many microfabrication processes such as doping ion. Access success in industrializing via post technology in coreless substrate production has broken the monopoly of leading global ic substrate manufactures and is seen as a major breakthrough in substrate development for china s semiconductor industry moving made in china to innovated in china. A compound semiconductor laminate substrate comprising two single crystalline compound semiconductor substrates directly bonded together and laminated the single crystalline compound semiconductor substrates having the same composition including a and b as constituent elements and having the same atomic arrangement characterized in that the front and back surfaces of the laminate substrate.

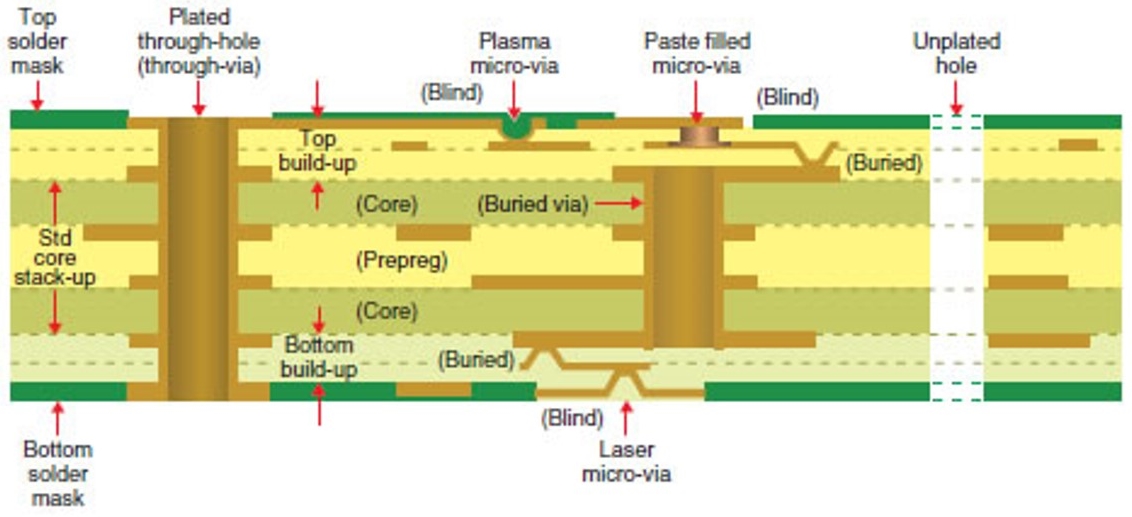

Substrate layout design rules varies from different suppliers. Magnetic and ferroelectricity film substrate. Substrates can be made by different materials. Substrate design consists of layout of all signals from the package external balls to the bump pads.

We present the advanced coreless laminate substrates in this paper including 3 layer thin substrate built by ets embedded trace substrate technology 3 layer sutc simmtech ultra thin substrate with carrier for fan out chip last package and 3 layer coreless substrate with hsr high modulus solder resist for reduced warpage. Laminate build up ceramic and more. Laminate packages employ a bga design which utilizes a plastic or tape laminate substrate over a leadframe substrate and places the electrical connections on the bottom of the package rather than around the perimeter. Evident by the hundreds of billion units shipped each year leadframes remain a key substrate technology for packaging semiconductors.

Meanwhile substrate based packages fall into several categories such as ceramic and organic laminate. In electronics a wafer also called a slice or substrate is a thin slice of semiconductor such as a crystalline silicon c si used for the fabrication of integrated circuits and in photovoltaics to manufacture solar cells the wafer serves as the substrate for microelectronic devices built in and upon the wafer.