Self Edge Plastic Laminate Countertop

Standard lengths of 8ft 10ft and 12ft.

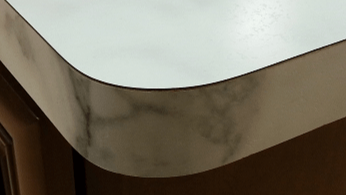

Self edge plastic laminate countertop. Laminate countertops make meal prep and clean up super easy. Wilsonart a world leading engineered surfaces company is driven by a mission to create surfaces people love with service they can count on delivered by people who care. You can even get laminate that looks like nature stone. The company manufactures and distributes high pressure laminate quartz solid surface coordinated tfl and edgebanding and other decorative engineered surfaces for use in the office education healthcare residential.

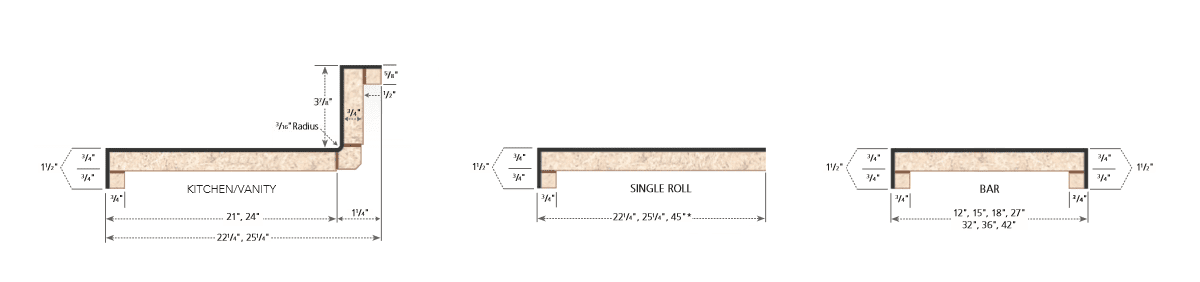

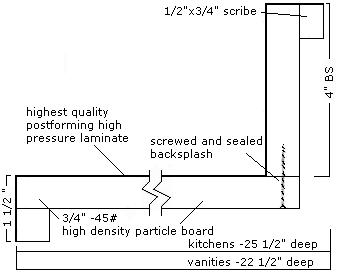

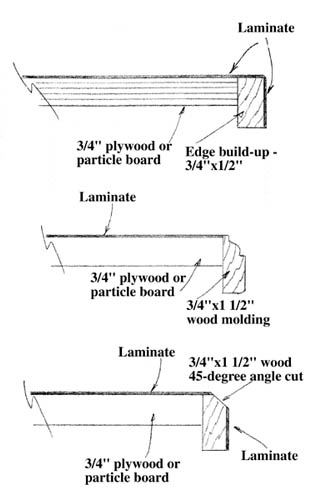

Offering matching textures and designs wilsonart edgeband is a cost effective edge solution for all your commercial projects. Laminate edge profiles wood edge bring nature into your home with a wood edge countertop. Standard depth of 25 1 4 with a backsplash. Self edge and post form.

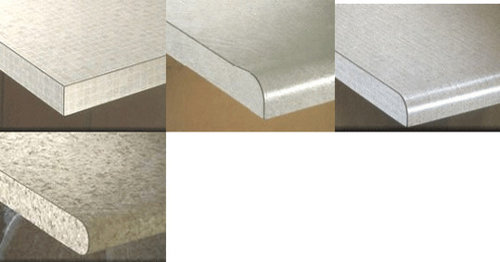

The classic method of dealing with unfinished countertop edges is known as edge banding and the most common form of banding are strips of the same laminate used for the top. We can also fabricate in store for you to install. The laminate is rolled over to. Moisture penetration can destroy a countertop.

Classic edge countertops are special order countertops that take approximately 2 weeks with any wilsonart or formica laminate color and can be ordered for kitchens vanities single rolls and bars. The edge can be square or angled using hickory oak or maple. Self or wood edge plastic laminate countertops are also very popular for those who chose to have few or no surface seams. This countertop style is typically fabricated and install on job site.

Self edge or wood edge laminate. Available in 4 6 8 10 and 12 foot lengths depths of countertops vary not shown in picture. Custom edge tops can not have radius corners. Stained can be applied to match existing surroundings.

At last an edgeband solution for cabinets doors drawers shelves tables fixtures and countertops that complements more than 200 wilsonart laminate designs. Here is the difference between the two along with some pro s and con s of both. In this style the top shop uses substrate for the countertop out of mdf or particle board and then glue sheets of laminate to the substrate using contact cement. Post form these types of countertops are manufactured by adhering laminate to a particle board substrate with a formed edges and or backsplash.

Laminate countertops can take kitchen wear laminate can handle hot pots and pans up to 400 degrees just fine. There are two types of laminate countertops.