Selective Deposition Lamination Definition

The first commercial 3d rapid prototyping based on fusion disposition modelling was introduced in april 1992.

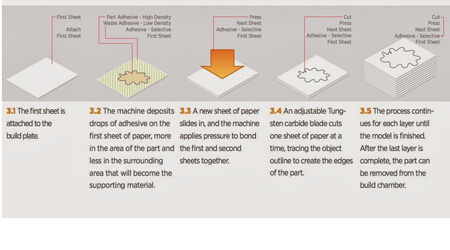

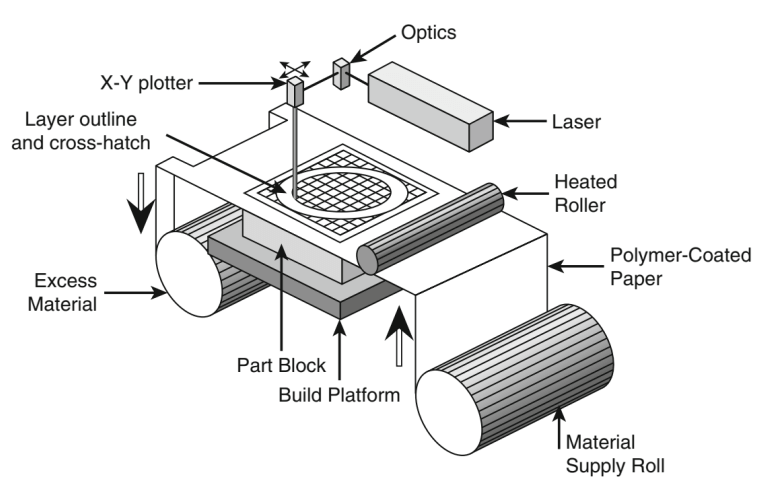

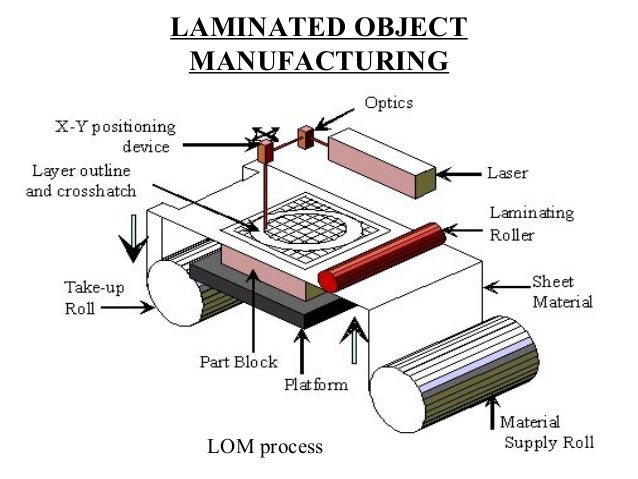

Selective deposition lamination definition. The process involves layers of adhesive coated paper or plastic or metal laminates that are successively glued together with a heated roller and cut to shape with a laser cutter. History of rapid prototyping. Selective deposition lamination refers to the ability to selectively apply a binding substance or heat and pressure to adhere layers of material. Selective deposition lamination sdl 3.

Selective deposition lamination sdl. The iris was the world s first full colour 3d. Mcor technologies have three 3d printers the mcor iris mcor arke and matrix 300 all of which utilise selective deposition lamination. Selective deposition lamination sld is a 3d printing process using paper.

The following additive manufacturing am systems fall into this definition. On the sheet of paper glue is. Fused deposition manufacturing fdm 2. Details are created on a building platform which is supplied with a sheet of paper from a feed roller.

Selective deposition lamination refers to the ability to selectively apply a binding substance or heat and pressure to adhere layers of material. Ultrasonic additive manufacturing is a variation of sheet lamination in that it uses ultrasonic vibrations to bind different materials into a solid object. Sheet lamination can also be known as in alphabetical order. Additive manufacturing method where the cross section of the detail is cut into paper which is then successively glued to the previous layer.

Transparent selective coatings are characterized by a high transmissivity for solar radiation and a high reflectivity for long wavelength infrared radiation. This process is similar to laminated object manufacturing lom rapid prototyping method. Selective coatings are applied by elec trodeposition vacuum deposition or painting. This 3 d printing technology is the most flexible low cost and a popular method of 3 d printing today.

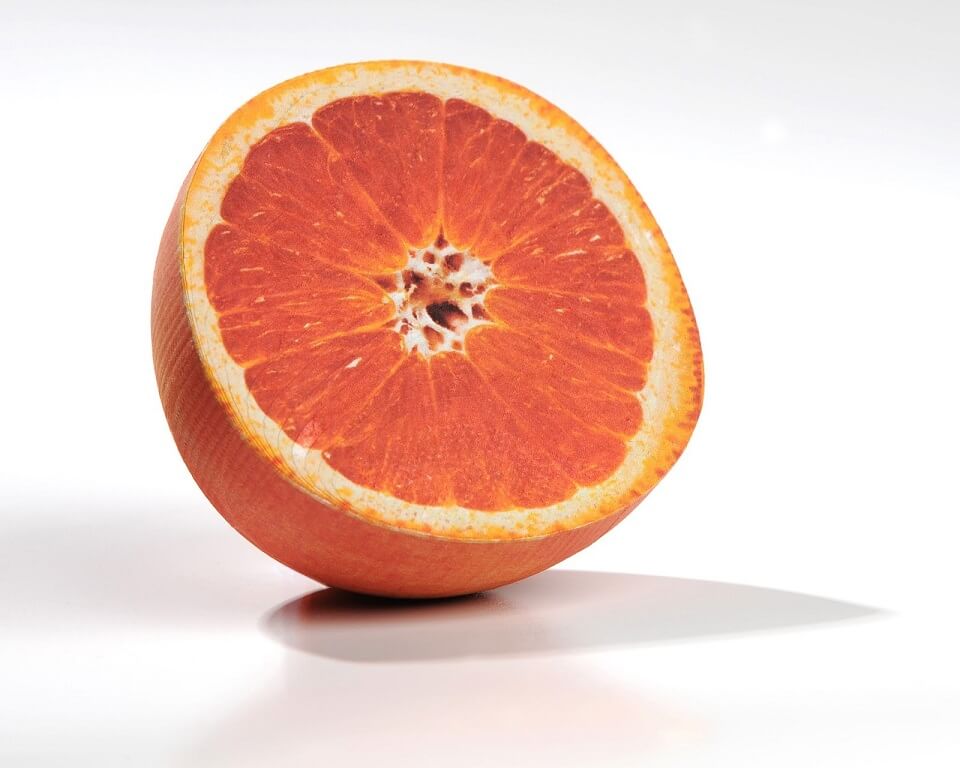

Rapid prototyping was introduced in 1987 with the introduction of stereolithography technology followed by selective layer sintering fused deposition modelling and laminated object manufacturing. Computer aided manufacturing of laminated engineering materials or cam lem 2 laminated object manufacturing or lom 3 plastic sheet lamination or psl solidimension ltd selective deposition lamination or sdl mcor technologies ltd. Using our patented selective deposition lamination sdl technology the cg 1 3d printer uniquely uses inkjet printheads with specialized paper and adhesive to build full colour robust textured heat resistant durable and effective 3d models. The result was selective deposition lamination and their vision to make 3d printing accessible to all was achieved in the co founding of mcor technologies.

Create full colour environmentally friendly 3d prints with zero dust or emissions.